The ESP vacuum dryer, with heating plates, is the most suitable model for carpentries, furniture manufacturers, for drying "live edge" shaped boards up to 100 mm thick, for drying semi-finished products (for the production of musical instruments, rifle stocks, baseball bats, etc.), or for drying lamellas used for the production of fine flooring. Suitable for soft wood (fir, pine, larch, etc.) and hard wood (oak, walnut, chestnut, ash, maple, etc.).

This type of dryer ensures the highest performance in terms of drying speed.

The technology adopted is based on the use of heating plates (electricity or hot water) and the use of a continuous vacuum.

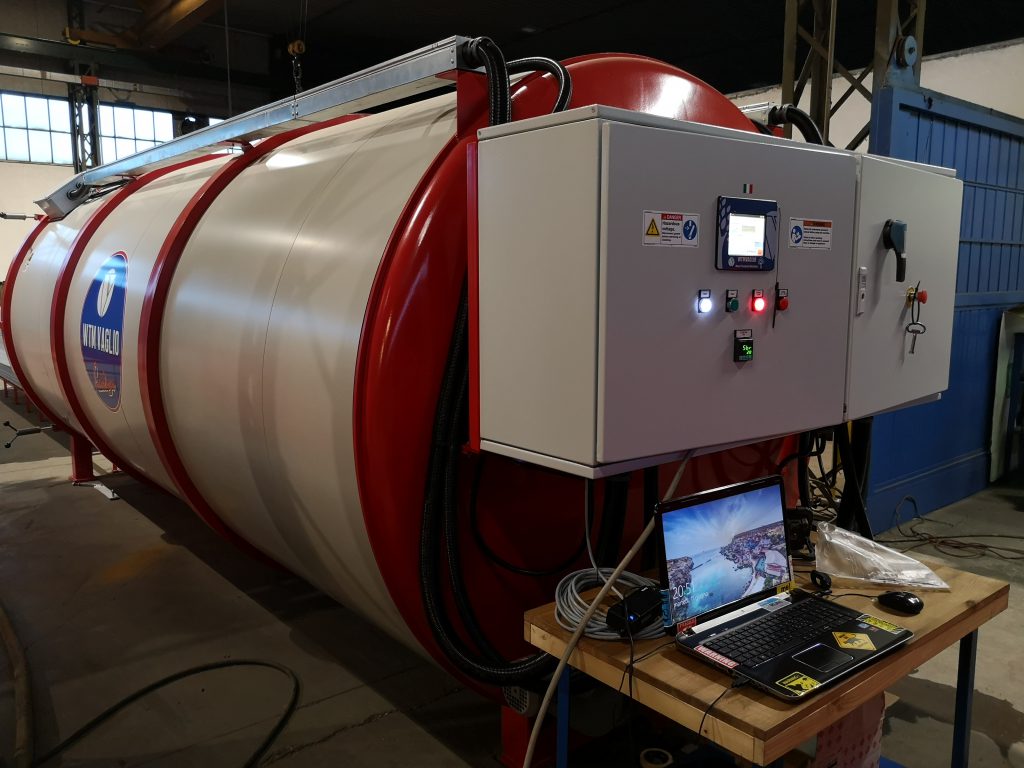

A simple but effective control system ensures quality drying and if necessary, our technicians can remotely monitor your plant in real time!

You select the type of wood and the thickness, and all you have to do is click on the start button to start the automatic drying cycle!

STANDARD DIMENSIONS FOR ESP DRYERS

| diameter (mm): | 1.000 | 1.300 | 1.600 | 2.100 | 2.600 |

| stack (H x W): | 500X800 | 850X960 | 1.050X1.100 | 1.350X1.400 | 1.395X1.932 |

Length (usable): from 4 m to 12 m

Special, non-standard dimensions are available on request.

| Fast drying time | up to 20 times faster than conventional dryers; | |

| Reducing energy costs | up to 50% compared to conventional drying: fast time and low temperatures minimize heat loss from vacuum drying chambers; | |

| Final humidity | high uniformity in the final moisture content (6-8%); | |

| High quality drying | less cracking and splitting (due to low temperatures); less internal stress (due to lower humidity gradients); | |

| No discoloration of the wood | drying in the absence of or with little oxygen prevents the oxidation of certain natural wood components. Precious woods keep their beautiful grain unaltered; | |

| Absence of harmful emissions (VOCs) into the air | (VOC = volatile organic compounds): the vacuum drying process takes place in a completely hermetic autoclave. |